Characteristics and development trend of high power laser cutting machine

Release time:

2023-12-20 10:21

High power laser cutting machinecharacteristics and development trend

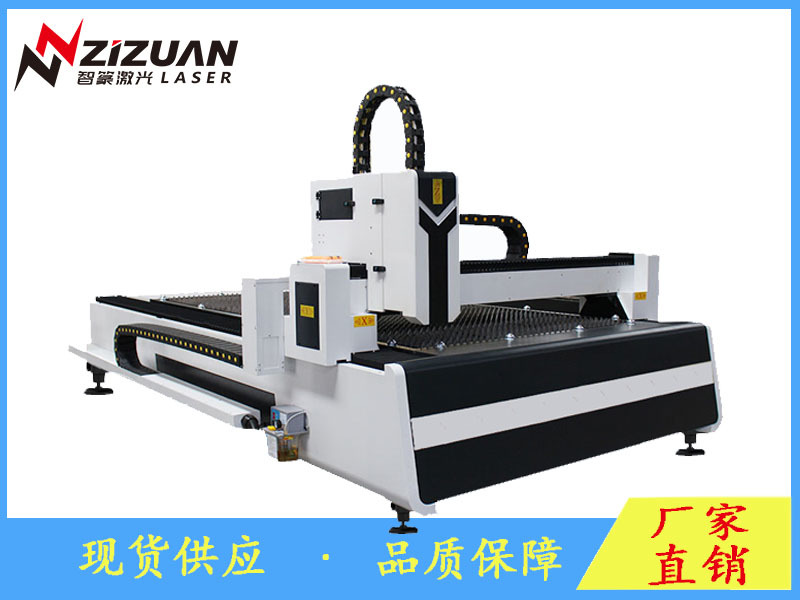

In recent years, the competition in the field of laser cutting machine technology is particularly fierce. From the rise of laser cutting machine enterprises, to the replacement of YAG, CO2 and other cutting machines by fiber laser cutting machines, to the introduction of high-power laser cutting machines, there is a trend of competition among enterprises. So, what are the characteristics of high-power laser cutting machine?

Laser cutting machine can be divided into low power, medium power and high power according to power. For thin carbon steel plates and stainless steel plates, low-power laser cutting machines can cut well. If it is to cut thick plates or improve cutting efficiency, high-power laser cutting machine can be better realized. In recent years, 10-watt fiber laser cutting machine has become a hot topic in the field of laser cutting. Many companies have launched high-power laser cutting machines, which seem to occupy the domestic and foreign markets.

High power laser cutting machineThe characteristics

1. High material cutting thickness.

Take aluminum alloy plate as an example. At present, the maximum cutting thickness of high-power laser cutting machine is about 60mm. It is believed that with the greater breakthrough of high-power laser cutting technology, the bottleneck of 60mm thickness will be "broken" in one fell swoop ".

2. The processing speed is fast and the material waste is small.

It is equipped with professional laser cutting heads, lasers and other core components, and the processing speed is faster than traditional cutting equipment. Moreover, the high-power laser cutting machine does not require additional molds when cutting the same material, which can reduce material waste and improve material utilization.

3. Large cutting width.

It can cut large width. Compared with kilowatt and hundred watt laser cutting machines, it can provide a larger cutting width and provide customers with more processing possibilities.

4. Automation

Its entire processing process can be described as automated, and the application of computer network technology has promoted the development of automated unmanned laser cutting technology. The market demand for the application of this technology is also increasing, which also makes the high-power laser cutting machine need to be fully automated for user operation.

What is the processing principle of optical fiber cutting machine and what are its advantages?

The processing advantages of laser cutting machine are as follows:

(1) High precision, fast speed, narrow cutting seam, small heat influence, smooth cutting surface without burrs;

(2) The laser cutting head does not touch the surface of the material and will not scratch the workpiece;

(3) The cutting seam is narrow, the local deformation of the workpiece is small, and there is no mechanical deformation;

(4) the processing flexibility is good, can process any shape, cutting pipe and other profiles;

(5) can cut steel plate, stainless steel, aluminum alloy plate, hard alloy and other materials of any hardness, no deformation.

The above is aboutHigh power laser cutting machineThe characteristics and development trend of the introduction, if there are other questions, welcome to consult us at any time.

Related News

2023-01-05

Matters of adequate preparation before the application of coil laser cutting machine

Matters of sufficient preparation before the application of coil laser cutting machine Try to laser cut raw materials. After laser cutting of raw materials, check the vertical angle of cross section, surface roughness and whether there is burr hanging slag.

2022-12-26

What are the important key points in the application of coil laser cutting machine

What are the important key points in the application of coil laser cutting machine It should be noted that the strict implementation of safety operation procedures for reprocessing, because this is a very accurate experimental instrument, a process of use, there is careful computer system manipulation, only according to the safety operation procedures set in advance to carry out the correct actual operation, can ensure the normal operation of the actual work.

2022-12-16

Application of Coil Laser Cutting Machine Technology Market Advantage in Machining and Manufacturing

Application of Coil Laser Cutting Machine Technology Market Advantage in Machining and Manufacturing Laser cutting technology is widely used in the processing of hardened steel grinding tools and alloys and other parts. It is also very suitable for the production and processing of narrow slits and complicated fine parts. The advantages of laser cutting technology can be reflected in the production and processing of extrusion dies and stamping dies.

2022-12-06

What is the role of high-power laser cutting machine in the hardware industry?

High-power laser cutting machine in the hardware industry to play what role? The traditional hardware processing equipment is completed with a punch, a combination of polishing, cutting, bending and other processes. This kind of processing efficiency is relatively low, making a mold takes a long time and costs a lot. In addition, the country attaches great importance to energy conservation and environmental protection in the past two years, which has a certain impact on the hardware processing industry.

2022-11-28

How to use and maintain high-power laser cutting machine?

In order to ensure the normal use of high-power laser cutting machines, it is necessary to carry out daily maintenance of the equipment. Master the operation essentials of the equipment, you can easily cut the desired workpiece effect and extend the life of the high-power laser cutting machine. Here are some tips for daily use and maintenance.