What are the advantages of high-power laser cutting machine?

Release time:

2023-12-20 10:20

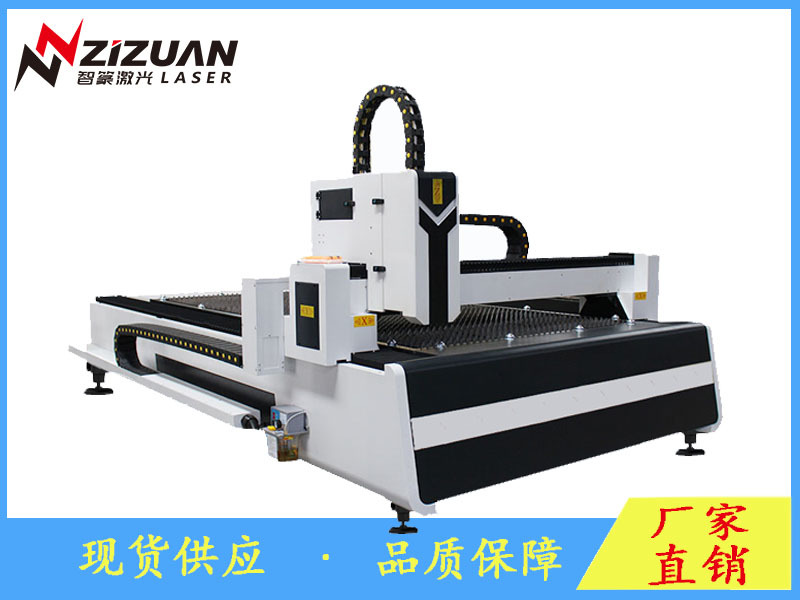

in recent years,High power laser cutting machineBecome a hot topic in the field of laser cutting, many companies continue to launch more than ten thousand watts of fiber laser cutting equipment. For the sheet metal processing industry, the birth of high-power cutting equipment has greatly improved the thickness and efficiency of sheet metal cutting. The emergence of this high-power cutting machine has continuously broken the limit of material cutting thickness. This reduces the price of processing thick plates, forms a good cycle, and further expands the application field of laser cutting. So what are the advantages of high-power laser cutting machine?

(1) High speed

The laser cutting speed has exceeded 20 m/min, the two-axis moving speed of the cutting machine can reach 250 m/min, and the acceleration rate can reach about 10g during operation.

(2) High precision

A hole of about 10mm in a 1mm thick plate can cut about 500 holes per minute. These holes have very little error in the cutting process.

(3) to the thick plate direction.

The power of high-power laser cutting machine is gradually increasing, and the corresponding thick plate size is also increasing.

High power laser cutting machineApplication:

Due to the high power, the high-power laser cutting machine has no problem when cutting plates and workpieces of various thicknesses. This fully shows that the high-power laser cutting machine is a kind of special cutting plate and workpiece numerical control equipment. High-power laser cutting machine can be widely used in steel, metallurgy, industrial manufacturing, shipbuilding, aerospace, railway and other large-scale engineering construction.

Mechanism of high power laser cutting machine

Structure: The whole structure is fixed by the workpiece and the movable gantry. It is a two-axis linkage, three-axis control of CNC laser cutting machine, X, Y axis linkage to achieve plane cutting feed, Z axis floating tracking workpiece surface.

Drive: The three CNC axes are guided by the rolling guide rail pair, and the AC servo motor drives the ball screw pair to feed. Servo motor adopts brand, screw rod and guide rail adopt brand.

Control system: the use of professional PC industrial control computer and the United States PMC control card, easy to operate; professional cutting control software to support CAD graphics automatic programming.

Special laser cutting head: using brand sensor and cutting head, the cutting effect is OK.

High power laser cutting machineApplication areas:

It can cut all kinds of metal plates and pipes, and is mainly used for fast cutting of stainless steel, carbon steel, manganese steel, galvanized sheet, various alloy plates, rare metals and other materials.

Widely used in: kitchen appliances, sheet metal chassis, mechanical equipment, electrical equipment, lighting hardware, advertising signs, auto parts, display equipment, all kinds of metal products, sheet metal cutting processing industry.

Generally speaking, the high-power laser cutting machine has fast speed, high separation efficiency, and the cutting speed of the plate can reach tens of meters per minute; the cutting edge is of good quality, small deformation, and beautiful appearance; the imported guide drive motor and servo motor are adopted, and the cutting accuracy is high; Various graphics or text can be designed for instant cutting at will, and the operation is simple, flexible and convenient.

Related News

2023-01-05

Matters of adequate preparation before the application of coil laser cutting machine

Matters of sufficient preparation before the application of coil laser cutting machine Try to laser cut raw materials. After laser cutting of raw materials, check the vertical angle of cross section, surface roughness and whether there is burr hanging slag.

2022-12-26

What are the important key points in the application of coil laser cutting machine

What are the important key points in the application of coil laser cutting machine It should be noted that the strict implementation of safety operation procedures for reprocessing, because this is a very accurate experimental instrument, a process of use, there is careful computer system manipulation, only according to the safety operation procedures set in advance to carry out the correct actual operation, can ensure the normal operation of the actual work.

2022-12-16

Application of Coil Laser Cutting Machine Technology Market Advantage in Machining and Manufacturing

Application of Coil Laser Cutting Machine Technology Market Advantage in Machining and Manufacturing Laser cutting technology is widely used in the processing of hardened steel grinding tools and alloys and other parts. It is also very suitable for the production and processing of narrow slits and complicated fine parts. The advantages of laser cutting technology can be reflected in the production and processing of extrusion dies and stamping dies.

2022-12-06

What is the role of high-power laser cutting machine in the hardware industry?

High-power laser cutting machine in the hardware industry to play what role? The traditional hardware processing equipment is completed with a punch, a combination of polishing, cutting, bending and other processes. This kind of processing efficiency is relatively low, making a mold takes a long time and costs a lot. In addition, the country attaches great importance to energy conservation and environmental protection in the past two years, which has a certain impact on the hardware processing industry.

2022-11-28

How to use and maintain high-power laser cutting machine?

In order to ensure the normal use of high-power laser cutting machines, it is necessary to carry out daily maintenance of the equipment. Master the operation essentials of the equipment, you can easily cut the desired workpiece effect and extend the life of the high-power laser cutting machine. Here are some tips for daily use and maintenance.